Fabric formed earth roof design and construction for a doghouse

- Scarlett Lee

- Dec 1, 2021

- 6 min read

Updated: Aug 13, 2024

The roof design for Myeong-rang house was developed with consistent design iteration. The doghouse was designed and built not only to serve as a shelter for my beloved dog, but also to test flood resilient earthen construction technology I am developing for my PhD research. The initiative of my PhD research is to develop and deliver flood-resilient earthen construction technology for vulnerable communities in flood prone areas. In line with my research goal, the house has been designed considering three important factors: low-cost, locally available resources, and simple construction.

After a long consideration and research, I have decided to build a HyPar roof since its design and construction technology meets the three factors, and it can be built with fabric formwork I have been developing. HyPar roof, Hyperbolic Paraboloid, is initially designed by George Nez who contributed to building a simple, fast, and low-costroof construction for housing for displaced communities. His housing is called Latex Concrete Habitat by using Latex and concrete as major materials.

However, I have researched using alternative local materials instead of latex and cement that Nez used because these materials are neither locally available nor sustainable. Latex is not available in South Korea, and the use of concrete doesn’t fit with my research goal to develop flood-resilient earthen construction technology for the community living in where concrete is not affordable. Therefore, I have researched and conducted several tests to build a HyPar roof with locally available sources.

I have found that seaweed has been used a natural glue for mud plaster in South Korea, so I thought it could potentially be a natural substitute for chemical latex. (Seaweed is a popular food in Korea but I have come to know the first time that seaweed has also been used a construction material.) However, as the nature of vernacular construction technology, there was very little information about how to use seaweed as a material for a mud plaster. Since there was no way to find a perfect formula, I had to find out how they work through consistent tests.

The reason why sea mustard can perform as a natural glue is because of alginic acid that is viscous in contact with water. A high viscosity is found in Miyeokgui (미역귀) which refers to a specific part (similar with ear in shape) of sea mustard in Korean. For a test, I submerged miyeokgui (미역귀) in a bottle of water to see when it has appropriate viscosity to be used as a glue. By changing the amount of water and the submerged time, I found out that it has a workable viscosity when it is immersed in water for more than 2 and a half hours with the ratio – miyeokgui (미역귀) 1 : Water 10.

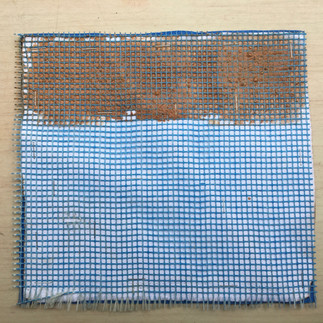

Once sea mustard glue is prepared, I mixed the glue with soil and applied the mixture to a fabric sample. The fabric sample was made of 3 layers – waterproofing layer, cotton, and fiberglass mesh, which is sample fabric layers of a roof that I planned to build. I plastered a mixture of miyeokgui glue and soil as a thin layer at a time, and applied this for 5 times layer by layer after a previous layer became completely dry. For a comparison, I conducted another test with a mixture of lime, soil and miyeokgui glue by applying the mixture 7 times to a fabric sample. Through the test, I found that a lime stabilised plaster has a thicker texture than unstabilised plaster and also dries quicker. Each lime stabilised sample and unstabilised sample were finished with only miyeokgui glue for three times.

Unstabilised mud plaster was applied to a fabric sample for 5 times

Once the two samples were completely dry, I observed them carefully. When I touched each sample, I found a great difference in texture and finishing. Unstabilised sample (a mixture of myeokgui glue and soil) was sturdy and fine particles didn’t come off much from it, while particles came off a lot from lime stabilised sample. It seemed that miyeokgui glue doesn’t work well with lime.

I conducted a test to examine in detail water absorption of the sample. For a test, a small amount of water was dropped by a dropper on the surface of unstabilised sample, and the sample was filmed being observed how long it took to absorb the water completely. According to several tests, at the unstabilised sample, it took average 2 hours for water to be absorbed completely. The result was far better than I expected, showing that unstabilised mud plaster mixed with miyeokgui would perform well with rainfalls.

Once a performance of miyeokgui glue with water is confirmed, I built fabric formwork for a roof construction. The timber frames I made was constructed with 45 degree sloped triangled timbers at the top to wrap fabrics. These were also supported with holed plywood at the corner in order to fix the roof frames firmly with 4 fully screwed bolts that were embedded in rammed earth walls. After the timber frames are firmly installed with nuts on the rammed earth walls, I laid strips of waterproofing layers overlapping about 2-3cm. Each strip was pulled tight and fixed to the timber frames with staples forming a hyperbolic paraboloid shape. Once the timber frames were fully covered with first strips of waterproofing layers, I laid second strips over them orthogonally to create a firm hyperbolic paraboloid shape. While overlaying waterproofing layers on the frames, I inserted EPS boards under the fabric as an insulation material.

Over the waterproofing layers, I laid a sheet of cotton and fibreglass mesh in order to apply mud plaster to them. I used around 3000 staples to fix the fabric layer firmly to the layers below. After the fabric formwork was completely installed, I applied mud plasters mixed with miyeokgui glue for 10 times layer by layer. A thin layer of a plaster was applied once and a next layer was applied next day giving a time that a previous layer was fully dry (Since a thin layer was applied, a day was enough to dry). I also applied extra miyeokgui glue without soil to them 4 times as an additional protective layer. Previously, I applied miyeokgui glue on the inner surface of the rammed earth wall of the Myeong-rang house, I found that it reduced the extent of coming off soil particles from the wall when the glue was applied more than 4 times.

Building Myeong-rang House from the summer of 2020 to the autumn of 2021, I have conducted experiments, research, and design relevant to my PhD research. Through the construction, I have found that a simple and sustainable construction requires a consistent design iterations and consideration, and the careful design and research process actually takes longer time than actual construction.

The project of Myeong-rang house was a great chance for me to develop the methodology and approach that are closely aligned with flood resilient earthen construction technology. Three important factors for the development of the technology were considered and applied throughout the project, which is low-cost, simple construction, locally available sources. As a significant aspect of my research is to deliver the flood-resilient earthen construction technology to low-income people in flood-prone areas, the doghouse was carefully designed and developed consistently asking these questions ‘is it simple to build with low-skilled workers?’, ‘Is it feasible to build with locally available materials sourced from my local areas?’ During the construction process, I have also asked the pedagogical question of how to deliver the hands-on experience to unskilled labours since flexibly formed rammed earth requires an in-depth understanding of the intrinsic quality of materials, which is different to the process and approach of rigid formed rammed earth.

Epilogue

After heavy rainfalls on 30 November, I have found that the mud roof was severely eroded revealing the fabrics underneath. Therefore, it has turned out that miyeokgui glue is not suitable for a waterproofing purpose, although it keeps soil particles from coming off. I am planning to repair the roof with lime stabilised earthen mixture.

Acknowledgement

I greatly appreciate the big and full support of my father. Thanks to him, I have been able to keep developing my PhD research and projects in South Korea.

Comments